Vision

Prisma

Our vision project is called PRISMA and stands for: Prototyping, Researching and Innovating vision technology for Smart Manufacturing Applications.

Within the PRISMA project, the partners are working on optical systems within production processes. Image processing techniques can be used in various ways in order to improve production processes. This research is done to enable faster and more efficient use of the specific hardware and software components in the design of “smart production processes”.

We innovate together. That’s why industrial companies such as IMS, AWL-

Techniek and SCM are working together at Perron038 and various educational institutes such as, Windesheim in Zwolle and the Fraunhofer Project Center (FPC) at the University of Twente. With this collaboration we want to develop an integral, adaptive vision technology system. The system can be integrated into existing and new production processes for various applications within the healthcare, food and HTSM (High Tech Systems and Materials) industry.

Two years of Vision Technology @ Perron038

Five partners, more than fifty meetings, eleven events, five demonstrators and two publications. These are the results of the first collaborative project at Perron038: Project PRISMA. In the past two and a half years, IMS, AWL-Techniek and Tembo have worked together with the Fraunhofer Project Center and Windesheim on concrete applications of vision technology. A […]

Event: Get started with Artificial Intelligence

Artificial Intelligence (AI) offers a lot of opportunities for the manufacturing industry. But where to start? Wednesday October 13th, visitors at Perron038 got inspired during the event ‘Get started with Artificial Intelligence’. Experts straight from businesses presented cases, experiments and successes with AI. Perron038 contributed to the event with presenting a case from project PRISMA. […]

Update II Project PRISMA

Prototyping, Researching and Innovating vision technology for For two years, within the PRISMA project, six partners of Perron038 have been prototyping, researching and innovating vision technology for Smart manufacturing applications. We are happy to give you an update on the developments after each semester! Use case IMS Commissioned by IMS, students have recently worked on three subprojects. One […]

EXPLORE THE POSSIBILITIES OF AI

Producing more efficiently, collecting more data and creating more value at lower costs. These are objectives that play a big role in many companies. But how can engineers contribute to achieving these goals? Smart technologies play a big role in this already and will cause a big transformation in the coming years. Looking at artificial […]

Update Project PRISMA

For two years, within the PRISMA project, six partners of Perron038 have been prototyping, researching and innovating vision technology for Smart manufacturing applications. We are halfway through the project and are happy to give you an update on all the developments! USE CASE IMS Students have recently conducted an exploratory study on the possibilities for […]

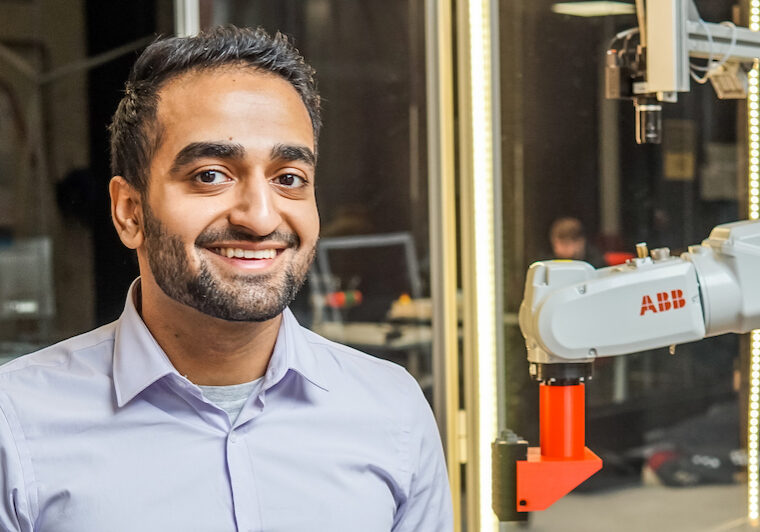

STUDENT SPEAKS: Shekib Hamidi

One of the students who conducted research within the PRISMA Project last semester is Shekib Hamidi. Commissioned by AWL-Techniek, he investigated how 3D laser triangulation can be used for quality control of an object. Shekib: “Within this research I have not only learned about laser scanning but by the degree of independence and guidance from […]

WHAT WE DO WITHIN THE PRISMA PROJECT

1

Gain knowledge and insights into the use and application of various vision

techniques.

2

Develop data acquisition systems and methods within industrial processes based on vision technology, such as sensoring systems. Its integration is focussed on control systems for advanced manufacturing production processes in order to optimize production and make it more accurate, within automated quality control.

3

The development of data analysis systems. This mainly concerns product quality

inspection and automatic learning processes.

4

Nurturing a creative collaborative environment to ensure new developments

around vision technology can be shared with entrepreneurs, educational institutes and government.

WHAT WE WOULD LIKE TO SEE AS A RESULT

- 1

PHYSICAL TEST-FACILITY

A physical test-facility and an experimental environment where research can be carried out. This research is about characteristics of the application of vision technology aimed at production accuracy and product quality control.

- 2

FOUR DEMONSTRATORS

Four demonstrators of innovative vision modules that can be integrated into the various application areas of all partners involved. The working prototypes form the basis for product/process development at the industrial partners. They are intended for both internal use (process improvement) and commercial applications.

- 3

STATE-OF-THE-ART-KNOWLEDGE

State-of-the-art-knowledge about the industry and opportunities of advanced vision technology. This knowledge is shared with other companies in the Zwolle area and with technical educational institutions. We organize workshops and events around the test set-up and demonstrators in order to create awareness and share knowledge about Advanced Manufacturing.