Additive manufacturing: the process of building a model layer by layer from a 3D design (or CAD data). It is a technology that has become indispensable in many industries. In the factory at Perron038, you will therefore find a unique combination of machines to get started yourself.

Powderbed 3D printing, Meltio and Coldspray: a combination of these three techniques that you won’t find anywhere else in Europe at the moment!

Machines in our additive manufacturing lab:

- Titomic Cold Spray 3D-printer

- Haas CNC with Meltio 3D-printing

- MiniFactory Ultra 2

- GE Additive M2 Series 5

- GOM ATOS Q 3D-scanner

Titomic Coldspray

Coldspray: it is a relatively new spraying technique using cold gas. At supersonic speed, particles of metal are shot away, deforming and melting the material. Thus, an object can be built up layer by layer.

The Titomic Coldspray performs under high pressure, allowing harder metals to be used, such as titanium. Cold gas spraying has all the advantages of traditional heat-based spraying techniques, but not the disadvantages. For example, there is no tensile stress during the process, no heat is needed, which reduces fire sensitivity during the process.

Advantages:

- Using materials efficiently, saving on raw materials and reducing waste. Coldspray is a sustainable solution.

- There is no limitation in the size of the object (where there is with a 3D printer). You can print large objects more easily.

- It is possible to switch between different materials: this means multiple metals can be sprayed on top of each other.

- Something can be added to existing objects, such as a coating, e.g. for repair. This allows parts to be used for longer. But an object can also be built from scratch.

- Large hourly output (kg/hr).

Getting started at Perron038? Examples:

- Investigating the use of Coldspray in repairing wear parts.

- Repair of casting parts.

- Printing a replacement part that no longer has a mould.

Check Titomic’s website for all options and materials »

MiniFactory Ultra 2

This plastic 3D printer is an advanced version of the printers you see in more and more businesses and classrooms. This printer allows you to use high-quality materials (polymers). Uniquely, it combines the ‘oven temperature’ of 250 degrees with a nozzle (extruder) that prints up to 480 degrees Celsius. The combination of these temperatures allows you to apply difficult-to-process plastics (such as PEEK, PEKK, PEI, PPSU etc.). The printer is equipped with extensive process logging. In which, among other things, temperatures are stored and every layer of the product is captured on image for quality assurance.

Advantages:

- The convenience of 3D printing, but with high-quality technical plastics

- You can print parts used in high-temperature environments or exposure to chemicals

- You can print parts that are stronger than common plastics for 3D printing

Getting started at Perron038? Examples:

- We are currently exploring the possibilities of printing with PEEK. This high-quality plastic is used, for example, for implants or electrodes used at high temperatures.

Check out MiniFactory’s website for all possibilities and materials »

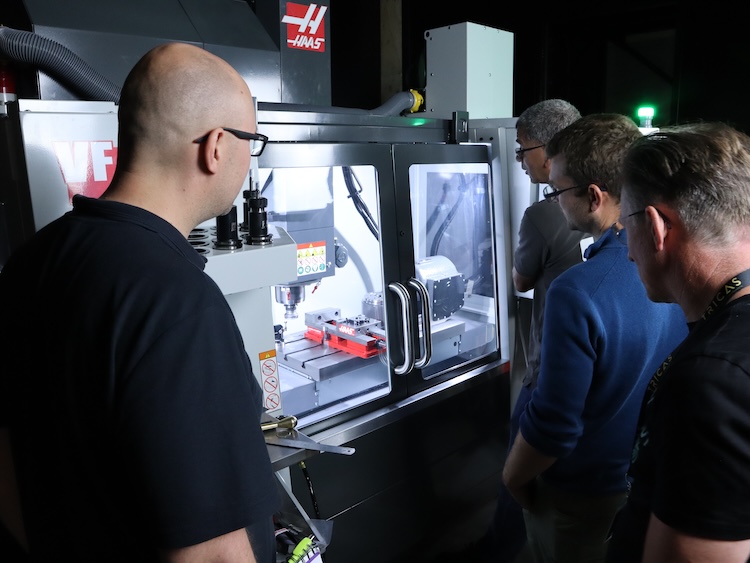

Haas CNC machine with Meltio 3D-printing

A five-axis CNC machine is used at many companies to produce components. The CNC machine at Perron038 has very complete metalworking options. But truly unique is the integrated Meltio 3D-print head. This 3D-print head is similar to laser welding. This allows machining to be combined with adding metal to the object. Machining, building up and post-processing all in one.

Advantages:

- Easy to use: the CNC machine’s normal mode of operation is already familiar to many companies.

- The 3D printing function combined with the accuracy of the CNC machine is unique.

- It is a relatively inexpensive technique due to the use of laser welding wire as raw material.

- 3D-printing an object can lead to less CNC operations. In comparison to traditional operations, which prevents waste of resources.

Perron038 is one of the first places in Europe, and the first in the BeNeLux to combine these two techniques in one machine setup!

Getting started at Perron038? Examples:

- Improving a part: by adding something to an existing object. Like a hook or a clamp.

- Possibility for the repair of worn-out or defective parts.

- Printing a part consisting of multiple material types, where the post-processing of the part is also performed directly in the machine.

Check the Meltio website for all possibilities and examples »

GE Additive M2 Series 5

Building a product from powder with a laser: that’s what this 3D metal printer from GE Additive can do. A technique that has already proven itself in the automotive and aerospace industries. The opportunities for the manufacturing industry are promising: that is why our machine park is equipped with this latest machine from GE: the first and currently the only one in the Netherlands. The machine is optimised for quality and reproducibility. It is equipped with two lasers, allowing you to print faster and with higher quality.

Advantages:

- Producing special parts that cannot be made with traditional techniques. Such as a duct with a bend, or a lightweight open structure as in a heat exchanger.

- Conscious use of raw materials: only the actual object is printed, so little raw material loss occurs.

- High accuracy compared to other methods of 3D metal printing.

- Faster production lead time: compared to casting or machining, 3D printing takes less preparation time. 3D printing does not require moulds, so it is possible to realise an object within a few hours.

Getting started Perron038? Examples:

- Printing repair parts in specific shapes.

- Experimenting with form-free design.

At the moment at Perron038, we print aluminium objects using this printer.

GOM ATOS 3D-scanner

This 3D scanner is specially designed for industry. Within the additive manufacturing lab, it is for example deployed prior to and after printing with one of the machines. You can also use the scanner to scan a part to then remake it (reverse engineering), also making any improvements. Or scan a printed object to check whether it meets quality requirements.

Advantages:

- Deployable at different points in a production process.

- Simple and convenient to operate.

- High accuracy.

- Software that makes it possible to present or compare results with CAD-data fast.

Getting started at Perron038? Examples:

- Measuring wear of metering slides

- Measuring handmade parts, in order to 3D print a prototype or make an object production-ready

- Scanning a gripper, to print a customised version

Lots of information and lots of opportunities! Would you like to work with one of the machines at Perron038? We would love to think along with you. Fill in the contact form below and we will contact you as soon as possible.