He is a familiar face at Perron038: the now graduated industrial product designer Tijmen Kraaij. The last year of his studies he focused on 3D metal printing technology. He carried out various assignments for the Lectorate of Plastics Technology, which is partly based at Perron038. Tijmen: “When I first heard about this technology six years ago, I immediately knew: I want to do something with this!

In September 2020, Tijmen is tipped off by his mentor to an assignment for a practice-based research group of the lectorate. It was a bull’s-eye when it turned out to be the metal 3D printer. “Actually, it had been my personal goal for years to get started with this printing technology. I really wanted to find out what the possibilities are, how it can be used and what I can achieve as a designer”, says Tijmen.

From mechanical engineering to industrial product design

Tijmen started his study career in mechanical engineering. In 2017, however, he decided to switch to the study Industrial Product Design (IPO), also at Windesheim. Tijmen: “The start as a mechanical engineer and the knowledge I gained then has helped me within IPO. I have learned that I can quickly master new techniques. I also familiarised myself with all kinds of software: without it, I would not have been able to realise the models I have now designed.”

Challenging assignments

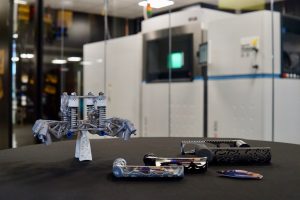

Tijmen discovered what high-end yacht building and metal 3D printing have to offer in his first assignment. “I designed a door handle for luxury yachts. I wanted to show how this printing technique can be used to customise and deliver unique, personalised products. This is particularly useful in yacht building: people want personalised products at all costs in order to stand out.” The assignment was to his liking and so he decided to do his graduation internship at the lectorate as well.

He had a concrete problem to work on: How can SLM (Selective Laser Melting) be used to make a flexible robot gripper? “It soon became clear that many factors had not been defined in the research. By asking a lot of questions, I was able to put the question in the right context and really start designing. says Tijmen. “This taught me that you have to keep asking questions, even when you think it’s already clear.”

Usable results

The result of his graduation period is a metal 3D printed gripper, realised in one print job. “The unique thing is that the hinges are also printed and that says a lot about the possibilities of this technique. I have shown that if you design lightweight and apply simulations to it you get very organic shapes. At the same time, the gripper is impact-resistant and meets the specified preconditions. continues Tijmen. His design is being further studied by the lectorate and the partners at Perron038 to see how it can be applied in machines. “I am really proud of that. Also the positive feedback from the companies. The gripper is used to inspire people and provide insight into technical possibilities.”

Perron038: ‘The best of both worlds’

Now that the start of his working career is imminent, Tijmen looks back on his time at Perron038. “I have felt very much at home there. It is a nice and open place. I consciously chose to gain a lot of knowledge in a free environment where you are not led by the corporate environment with, for example, frameworks and budgets. But at the same time, you do get to experience the team atmosphere and the knowledge present in the companies. For me, this was the ideal route to deepen my knowledge and specialise in this subject. This allows me to stand out in the next step of my career.”